- Home

- About HNAIKEN

- Quality Control

Quality is part of every aspect of our company. Featuring an outstanding management system and global certification, we can ensure the first rate quality. In order to provide the best products, our team is both honest and responsible, and we work with only the best internationally known raw material suppliers, including PPG paint and Chinalco coils.

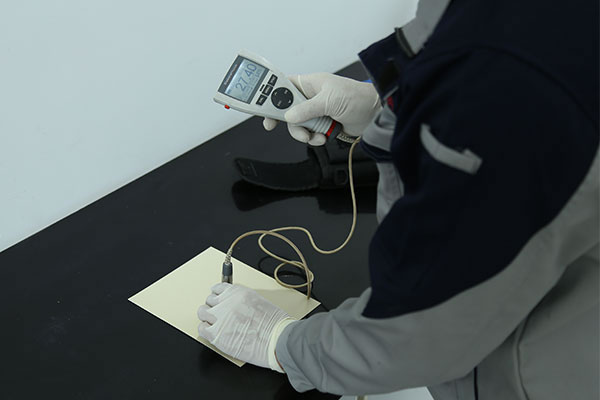

We have a complete detection mechanism to test the product quality before delivery, and all raw materials undergo a 48 hour test before manufacturing. These tests include impact resistance, pencil hardness, acid resistance, and alkali resistance, solvent resistance, boiling water, coated coil flexibility, color difference and gloss differences.

We have passed ISO9001 certification, and our products are sent to international authentication testing labs, including Intertec, TUV, and SGS to carry out tests and ensure the final quality. Our products have also passed BS EN 13501-1:2007+A1:2009 standards.

Once the panels have been delivered, we also keep track of the panels outside. We record the peeling strength and color difference every two weeks over a 2 month period.

-

T-bend test

T-bend test -

Color difference measurement

Color difference measurement

-

Dry film thickness test

Dry film thickness test -

Gloss test

Gloss test

-

Pencil hardness test

Pencil hardness test -

Cross-cut test

Cross-cut test

-

Impact test

Impact test -

Solvent resistance test

Solvent resistance test

-

Acid and alkali resistance test

Acid and alkali resistance test -

Determination of peel resistance by outdoor exposure

Determination of peel resistance by outdoor exposure

XINCAI AIKEN Metal Technology Co., Ltd.

Factory add.: North of Yueliangwan Road, Industry cluster of Xincai City, Henan Province, China

Jiangsu Branch

Add.: A503, Huajian Building, Shazhou West Street, Zhangjiagang, Suzhou, China

E-mail: sales@hnaiken.com

Taiwan Branch

Add.: Floor 1, No.28, Lane 10, Culture South Road, Sanchong District, New Taipei City, Taiwan Province, China

E-mail: twsales@hnaiken.com

Dubai Branch

BEONE MART TRADING LLC

P.O. Box: 22397 Dubai UAE

Tel: +971 4 294 16 50

Mobile: +971 50 628 51 08

Add: W/H. No. 6, Baghdad Road, AL Qusais Ind. 1, Dubai UAE